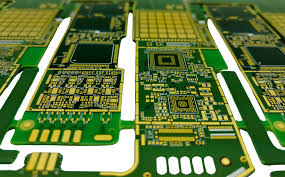

FR4 material is one of the best in the electronics sector due to its strong features. Due to its overall resilience, relatively low cost, and effective insulativity, industry professionals favor FR4 as the typical substrate for printed circuit boards (PCBs).

Excellent electrical insulation

When circuit integrity is key, FR4 material stands out for its excellent electrical insulation. The dielectric constant is stable between 4.0 to 4.5 at 1 MHz, providing consistent electrical performance. This high electrical resistance also means that FR4 does not form as parasite current paths protecting the functionality of the circuit.

Impressive Thermal Resistance

Another key advantage of FR4 is the excellent thermal resistance. Its high temperature of decomposition of ~ 285°C is greater than the maxium temperature in the PCB manufacturing and oprating process, meaning that it keeps its structure even if being exposed to high heat. It is a critical attribute as electronic devices become smaller and more power-dense and run at higher temperatures.

Cost Efficiency

Its low cost is antecedent to FR4 that also makes it so widely used. That is a way cheaper than quality is compromised solution and especially great for PCBs produced in a high volume. It offers a favorable cost-benefit ratio compared to alternatives such as metal-core or high-frequency laminates.

Mechanical Durability

One of the things worth mentioning is the mechanical strength of FR4. This is considered important to create robust PCBs to resist handling during assembly and usage, and achieves high strength to weight ratio. The toughness also enables the engineering of thinner, smaller PCBs that meet the miniaturization trends within electronics.

Wide Range of Applications

FR4 material has a found application in many different fields other than in consumer electronics, for example in automotive, aerospace or industrial electronics. This uniform performance rating in a wide range of environmental parameters establishes it as the material of choice in a myriad of high-demand sectors.

FR4 material still plays a core role in PCB manufacture, providing the thermal resistance, mechanical toughness, and cost profile to accommodate the increasingly challenging requirements of today's electronic designs. This in combination with the bulletproof reliability we demand of all our indicators have made it a staple in almost every type of application out there.